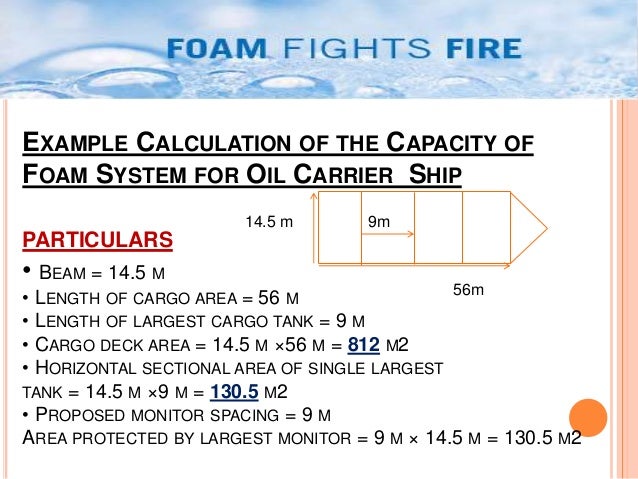

Foam System Design Calculation

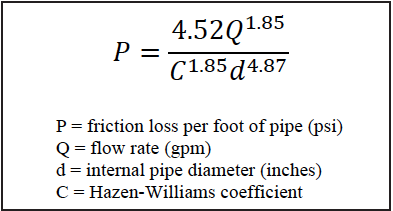

Foam system design calculation. 6400 x 03 192 gallons Number of sprinkler heads. Ft Under normal conditions an eight-pile platform will not have potential spill areas drip pans etc in excess of 600 ft2. In order to understand the simple formula it is important to know the components in a foam formula.

Structural foam molding process large load-bearing parts and assemblies can be produced with the optimum balance of functionality performance aesthetics and costs. We provided you with a calculation excel sheet below contains all calculation to design a foam fire suppression. The portfoilio offers UL Listed FM Approved configurations design flexiblity for utilization of inside or outside air supply and specific generator models for LNG hazards.

The user is responsible for the design and configuration of the system its appropriateness for the use intended and its compliance with all. Foam is a soft substance that is added to the water with a percentage of 3 to 6 this substance separates the surface of the fire from the air and thus reduces the oxygen level by 15 and then the fire is extinguished. Foam System Design Data In this section youll find our library of Technical Datasheets and Drawings for Viking foam systems.

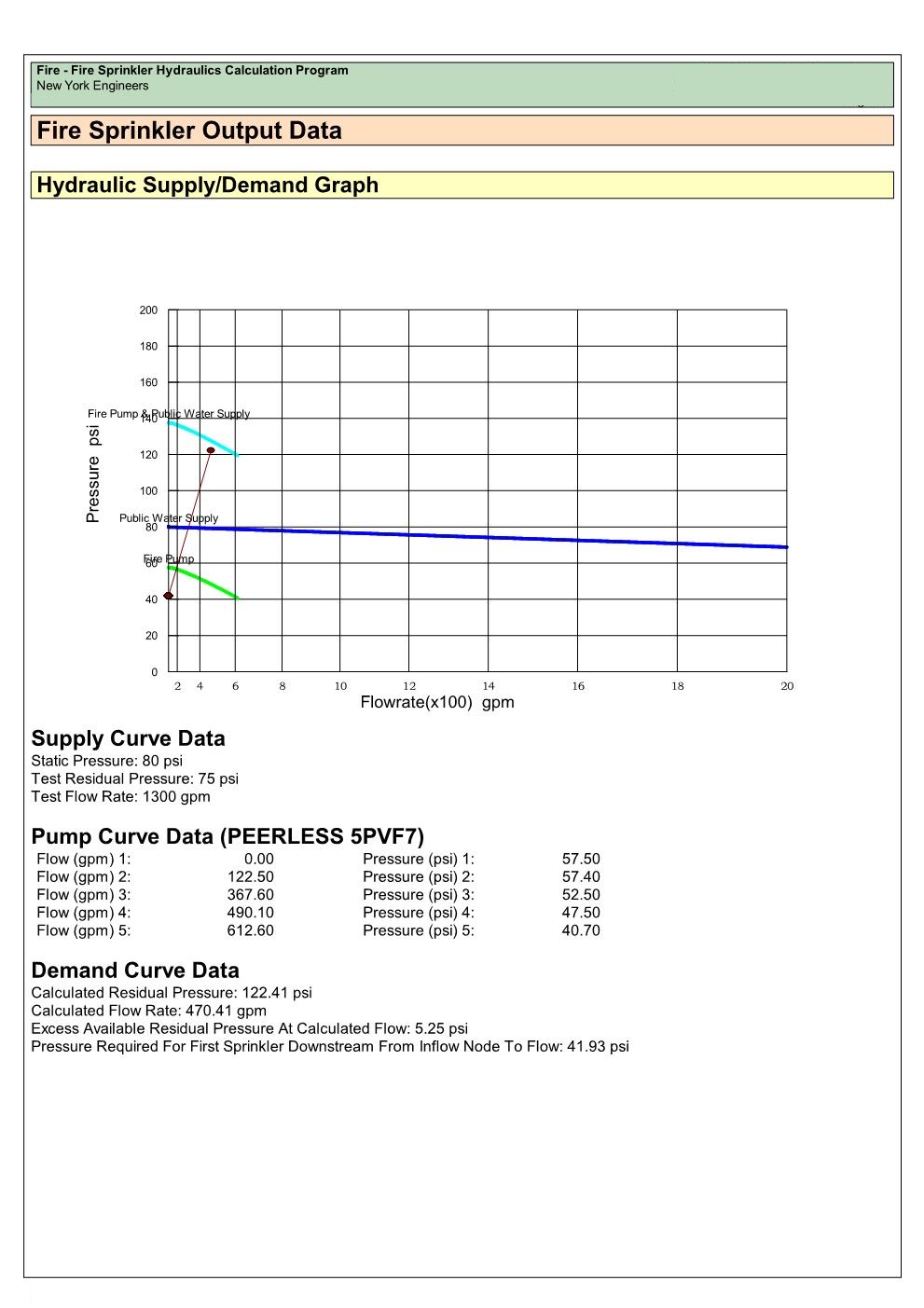

Taking into consideration this minimum density the foam solution shall be designed to discharge for a period of 10 minutes over the entire systems area for deluge and spray foam-water systems and over the design area design area is equal to 465 square meters in accordance with Paragraph 7371 of NFPA 16 for wet pipe dry pipe and preaction foam-water systems. Around the pump systems 9 balanced pressure proportioning 10 foam nozzles 10 application rates 11 post fire security 12 application techniques 13 class a foams 14 class a foam advantages 14 wetting agents 15 high expansion foams 15 foam fire protection for oxygenated and gasoline blended fuels 16 foam concentrate comparison chart 19 foam. 6622 LPM Foam Soln Rate for Dike3.

Todays innovative design engineers are capitalizing on the unique property profiles of foamable NORYL VALOX and LEXAN resins to design parts. Flow in GPM of foam solution. The application rate commonly referred to as density is frequently expressed in units of gallons per minute per square foot gpm ft2 or liters per minute per square meter Lpmm2 of area.

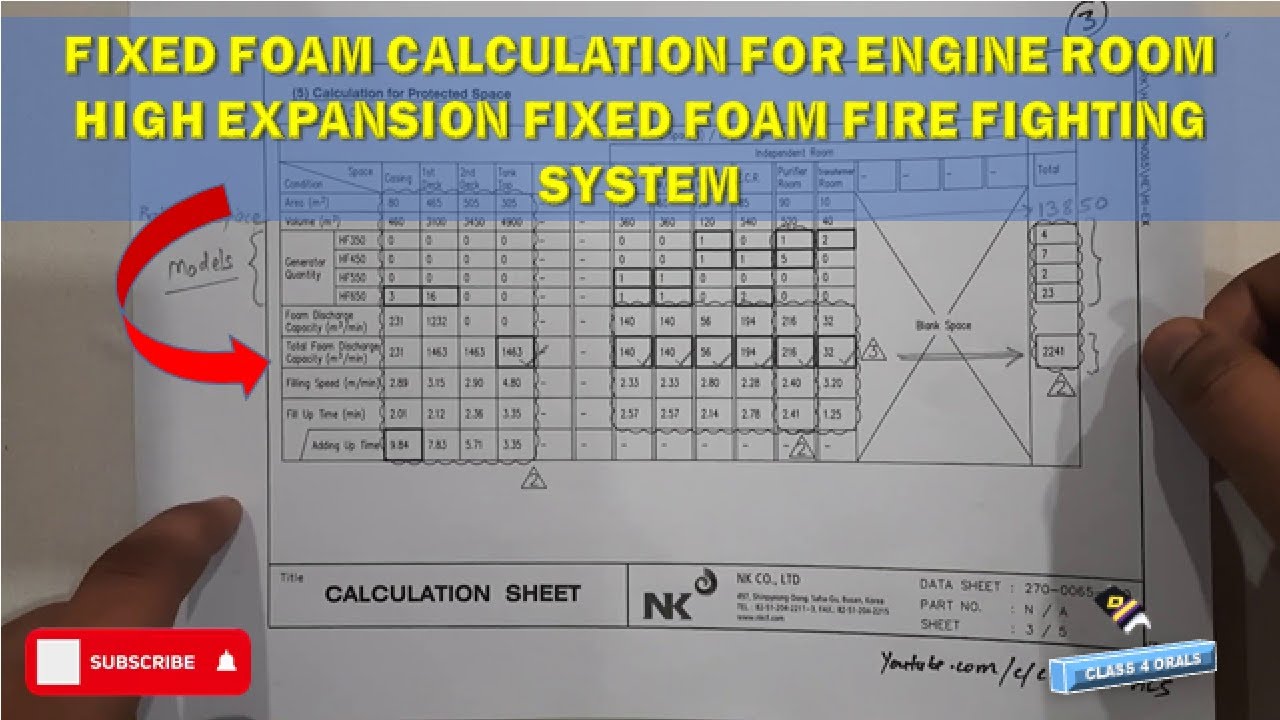

The formula for calculating the needed foam concentrate at a flammable liquid release is as follows. Design calculation sheet Project no. Foam Fire Extinguishing System Calculations.

16 x 4000640 Discharge Duration. The tank diameter is 100 feet so there for two foam chambers are required.

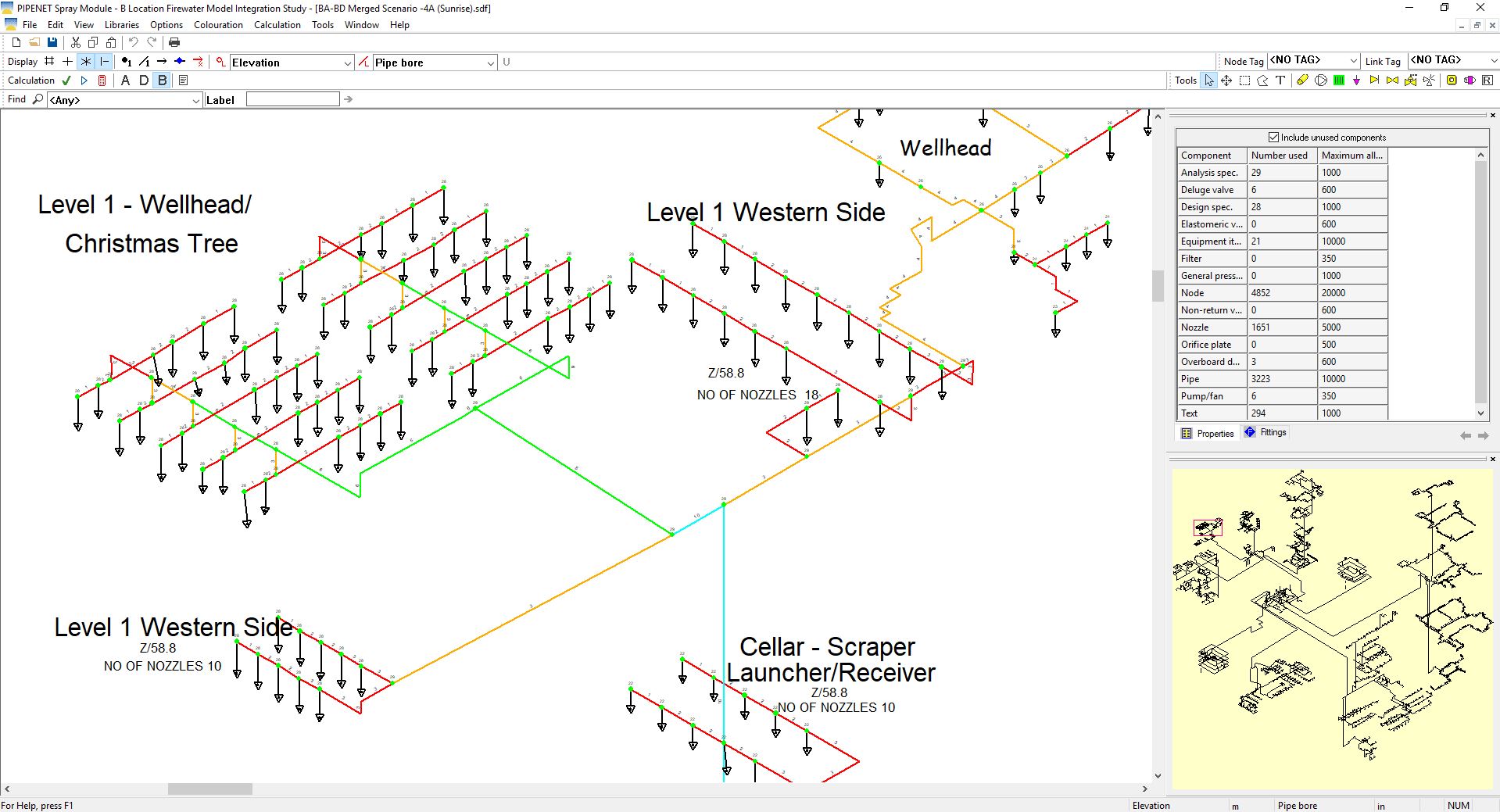

Full data from beginning to professional for foam fire fighting system design - thats part of lectures provided in fire matrix software.

Foam Fire Extinguishing System Calculations Excel Sheet. Flow in GPM of foam solution. The formula for calculating the needed foam concentrate at a flammable liquid release is as follows. Foam System Design Data In this section youll find our library of Technical Datasheets and Drawings for Viking foam systems. 4023-2-17 ENGINEERING MANUAL SECTION THREE PAGE 3. The tank diameter is 100 feet so there for two hose lines must flow at 50 gpm each for 30 minutes 7. Around the pump systems 9 balanced pressure proportioning 10 foam nozzles 10 application rates 11 post fire security 12 application techniques 13 class a foams 14 class a foam advantages 14 wetting agents 15 high expansion foams 15 foam fire protection for oxygenated and gasoline blended fuels 16 foam concentrate comparison chart 19 foam. By consolidating the calculations the system required on an eight pile consists of the following equipment. 1797 LPM Foam Soln Rate for Tanks3 Foam concentrate rate for Dike.

6622 LPM Foam Soln Rate for Dike3. Ft Under normal conditions an eight-pile platform will not have potential spill areas drip pans etc in excess of 600 ft2. The tank diameter is 100 feet so there for two foam chambers are required. Per sprinkler MAJOR FOAM SYSTEM. Todays innovative design engineers are capitalizing on the unique property profiles of foamable NORYL VALOX and LEXAN resins to design parts. The application rate commonly referred to as density is frequently expressed in units of gallons per minute per square foot gpm ft2 or liters per minute per square meter Lpmm2 of area. Full data from beginning to professional for foam fire fighting system design - thats part of lectures provided in fire matrix software.

Post a Comment for "Foam System Design Calculation"