Dust Collector System Design

Dust collector system design. The most basic type of dust collection system is a cloth bag attached to the dust port of a tool. The air filtration systems however will circulate the air in your workshop and collect dust that remains suspended for up to 30 minutes. Since a dust collector only captures dust in range of its suction you will not collect the fine particles that hang in the air.

1D3D and 2D2D are the most efficient cyclone collectors for fine dust particle diameters less. It removes 90 of the dust and wood chips and I didnt notice any drop in CFM. This is especially true for dust collector hood designs.

In order to create a first stage I added the 4 Oneida Super Dust Deputy Cyclone Separator Pictured Below which has performed like a dream so far. Easy fast to install just clamp together no rivets screws or welding needed. Remember Machines with the biggest draw highest CFM should.

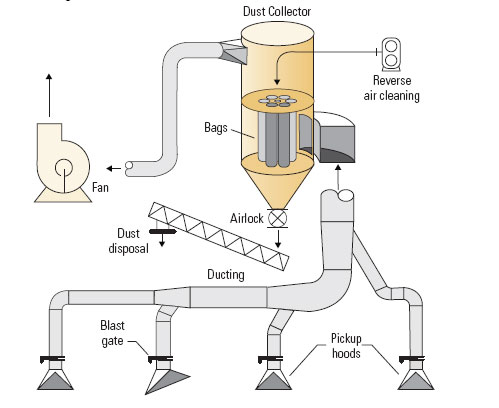

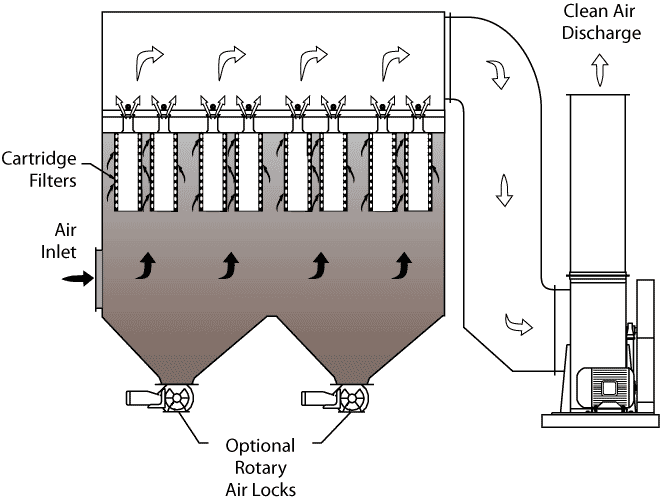

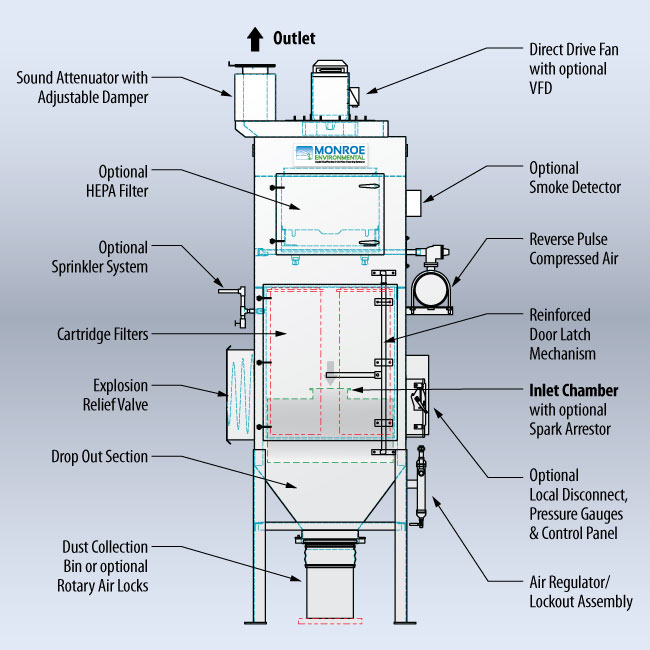

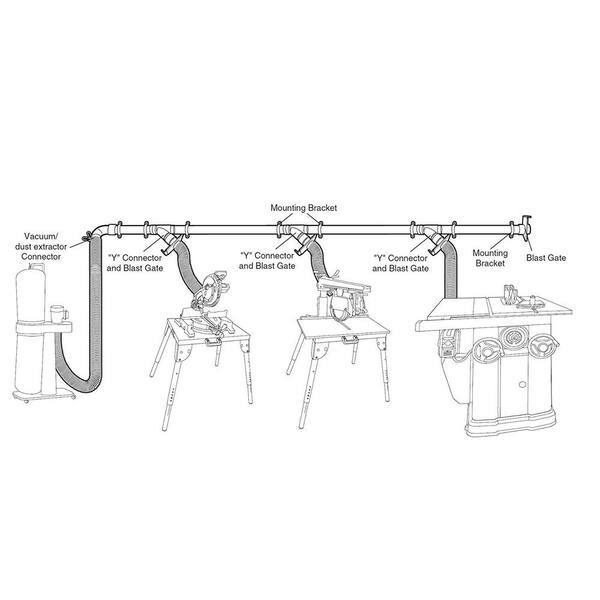

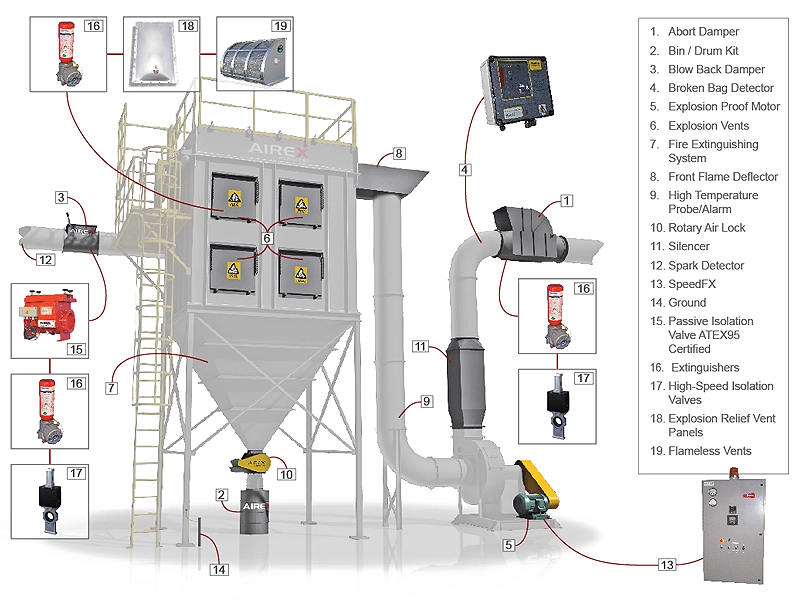

A wetdry vacuum connects to the dust port with a hose. The most commonly used dust collection system for dry dust collection utilizes pulse jet technology. Our dust collector ducting is designed to withstand high air pressure minimize air resistance and reduce static pressure loss making it ideal for material handling.

Adaptable to your existing ductwork. Savvy managers know their greatest asset is their people so its no surprise that worker comfort is a top priority for successful businesses. The primary goal of both systems is dust collection but they differ in various aspects.

Dust collector system designsystem pada alat penghisap debu dengan automatic cleaning. When the hose is too big for it you can use a reducer part to make it fit or even use duct tape. They mainly focus on installation or hw to grou.

Determine Diameter and CFM of Main Duct 5. Seal the port so there is a tight vacuum.

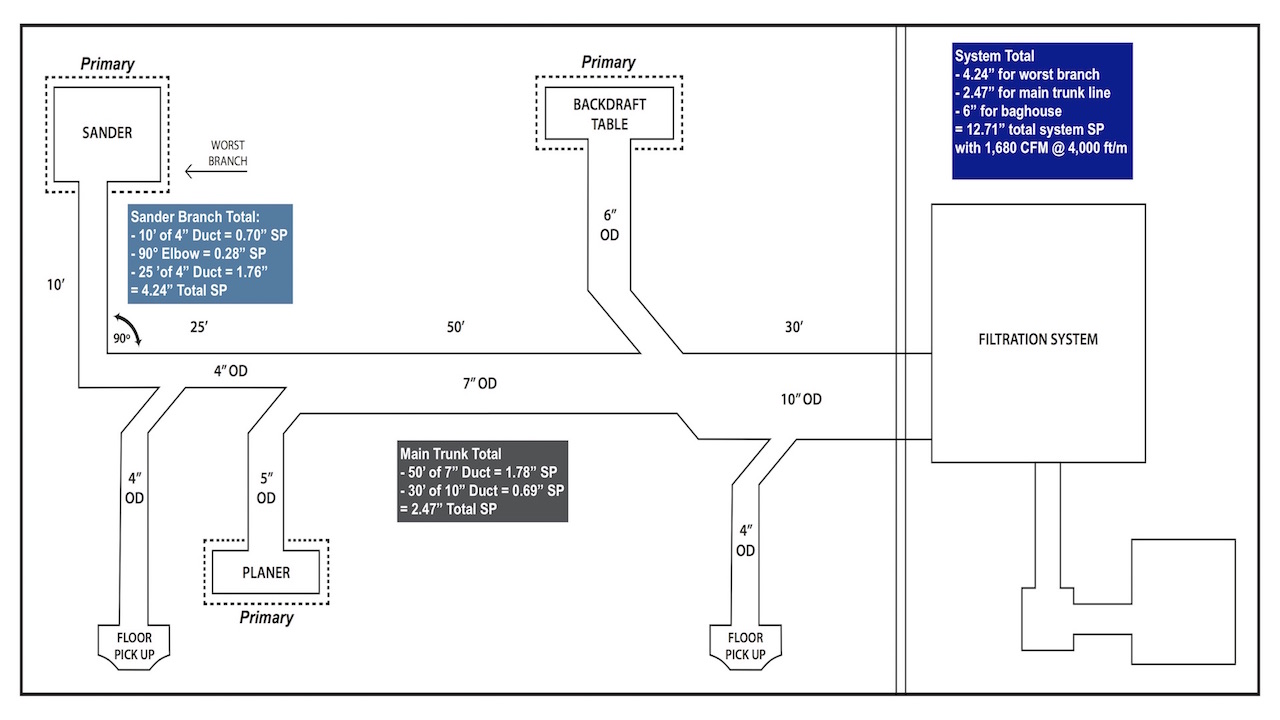

Draw a floor plan of your shop 2.

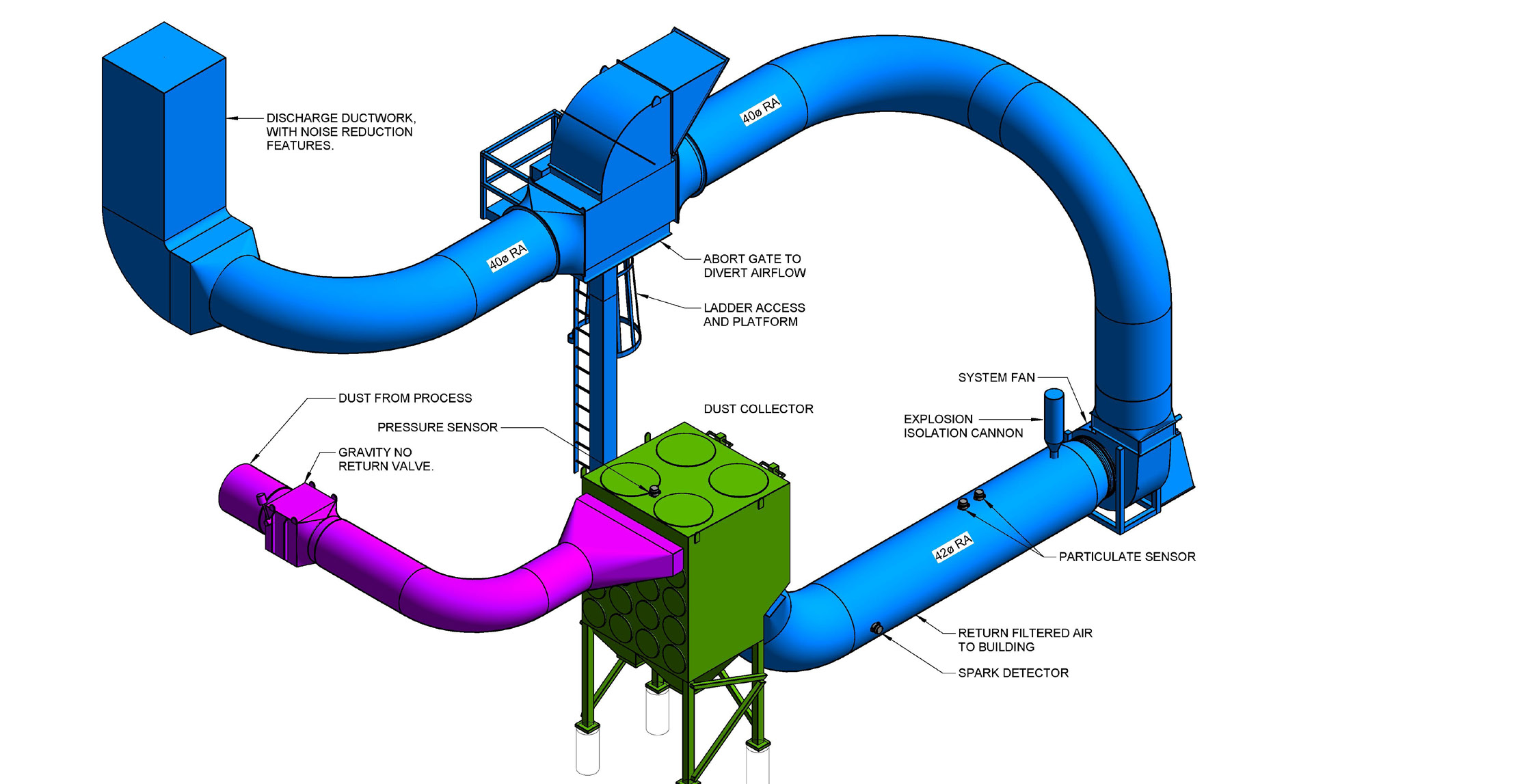

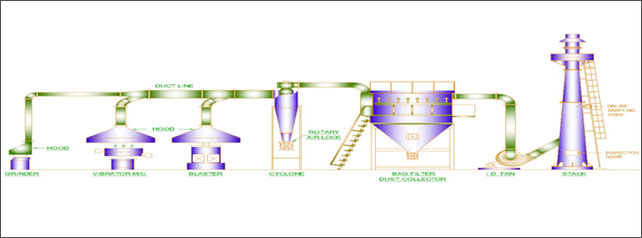

In some cases it may not only be dust that is conveyed as additional material like fumes. The most commonly used dust collection system for dry dust collection utilizes pulse jet technology. Adaptable to your existing ductwork. Determine Duct Velocity FPM 3. Dust collection duct design is a complex science and I am going to intentionally oversimplify it because I think the basics can be lost in. Dust collection system design in accordance with regulations consistent with material handling guidelines and safety requirements for your specific industry. Nordfab dust collection ductwork includes fittings and pipes that range from 3 - 24 in diameter and feature double-rolled connecting edges that clamp into place to provide heavy-duty seals. Easy fast to install just clamp together no rivets screws or welding needed. The first phase is sizing your duct work for adequate volume and velocity of flow for the type of dust you will be creating The second phase is computing the static pressure SP of your system to determine the size and power of your dust collection unit.

When balancing the airflow and more importantly air velocity in a dust collection system there are two main approaches. Local dealer support. A well-designed dust collection system has multiple benefits resulting in a dust-free environment that increases productivity comply with emission regulations and improve industry employee morale. Dust Collector Duct Design. The first step in designing your system is to draw a floor plan of your shop area including the following. The air velocity at the extraction point pick-up velocity must be high enough to capture the dust. Its always best to pair an air filtration system with a dust collector.

.jpg)

Post a Comment for "Dust Collector System Design"